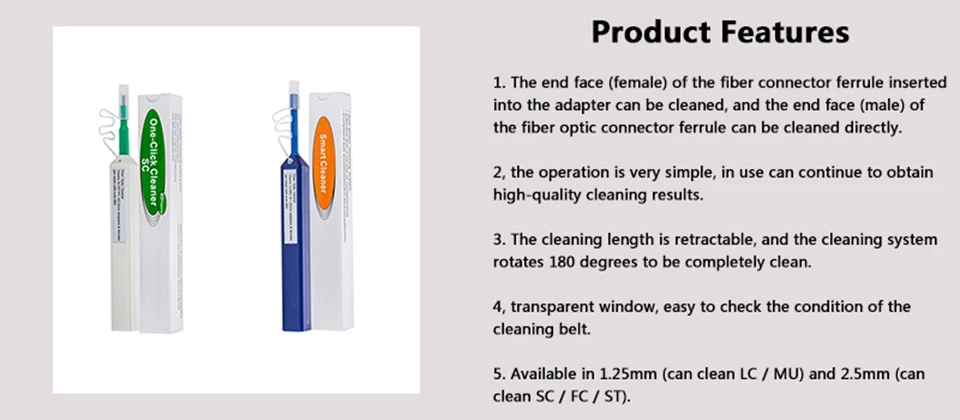

ONTi One-Click Cleaner Optical Fiber Cleaner Pen Cleans 2.5mm SC FC ST and 1.25mm LC MU Connector Over 800 Times

SPECIFICATIONS

Origin: Mainland China

Model Number: ONT-FCP-125

Connector Type: SC/UPC

Cleaning Connector Type: 2.5mm SC ST FC Ferrule End Face

Cleaning Adaptor Type: 1.25mm LC MU Ferrule End Face

Certification: CE

Brand Name: ONTi

2pcs FTTH Optical Fiber Pen Cleaner Tool: Connector Fiber Optic Cleaning Tools

One-Click Cleaner

ONTi provide fiber optic connector cleaners for fast and effective cleaning of connector end faces, including unused jumper connectors and connectors with adapters inserted.

It can remove dust, oil and other debris on the end face of the casing without damaging or scratching the end face.

Use a dry cleaning cloth to replace the solvent requirements. One-touch design, one push, one second cleaning, can clean more than 800 times 1.25mm LC / MU fiber connector and 2.5mm SC / FC / ST fiber connector.

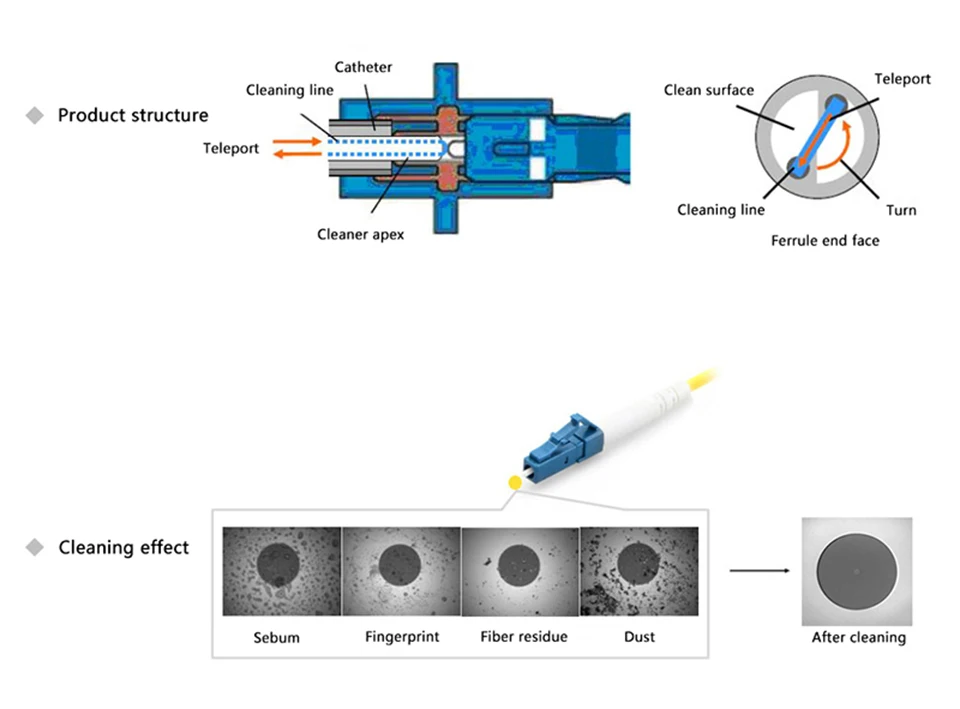

Product structure and Cleaning effect

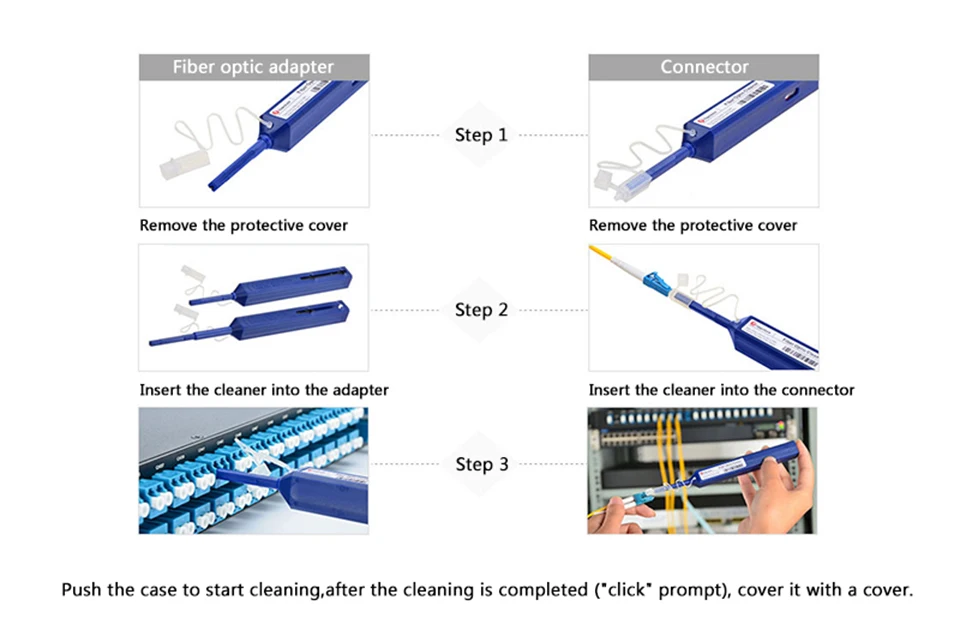

Optical fiber cleaner pen using steps

FAQ

Q: Why do we need to clean the fiber end face?

A: Generally, 90% of optical fiber connection failures are caused by contamination of the end face of the optical fiber. It is important to ensure that the end face of the optical fiber is clean for network transmission. Dirt or debris that accumulates between the two end faces of the connection can cause permanent damage such as cracks, scratches and dents.

Q: What happens if there is dirt or dust on the end face?

A: Contamination or dust on the end face of the fiber will generate heat and the fiber may melt.

Due to the light reflection wave, the laser is damaged and affects the entire communication system.

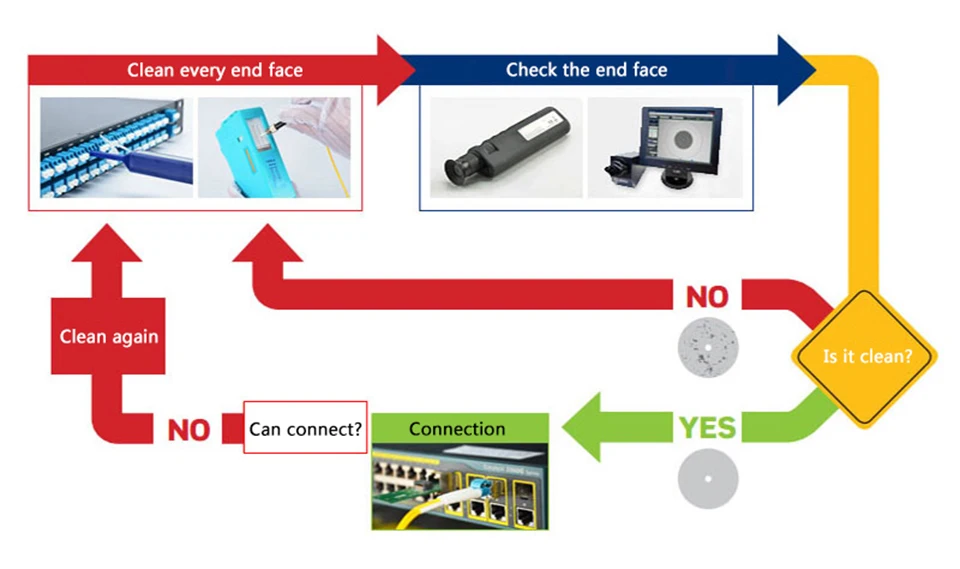

Optical fiber connector inspection steps?

1.Cleaning-Clean the end faces before all components are connected to avoid contamination

2. Inspection-Inspect the end face of each component under a professional fiber optic microscope. If there is contamination, re-clean and inspect (warm reminder: visible laser radiation may come out of the disconnected optical fiber or connected hair. View using optical instruments.)

3. Connect-Connect the parts immediately after the inspection is completed

4. Re-Clean-If disconnected, re-clean and inspect all parts before re-connecting

0097336119114

0097336119114

Contact us

Contact us

Track Order

Track Order

Cart

Cart

Sign in / Create Account

Sign in / Create Account